1. INTRODUCTION

The era of the Digital Transformation (DX) is characterized by the fusion of products and services, technology and emotions. And based on the development of intelligent information technology, innovative changes are expected throughout the industry. Data and knowledge will emerge as a new source of competition across the industry. Through this, productivity improvement or reduction of working hours occurs. Therefore, it will be accompanied by major changes in the economy and society based on major changes in existing processes. It is expected to change the industrial competition, centering on the platform and related ecosystem.

The Digital Transformation (DX) can be said to be an intelligent revolution of development and production in which advanced technologies such as artificial intelligence, robots, Internet of Things, and 3D printers are combined. Platform-based integrated services that connect products and services are becoming the mainstream, and a hyper-connected network environment centered on data services is being built. It is connected with the digital transformation of the enterprise and the existing environment and platform change. This means that it is no longer difficult to provide products and services that satisfy consumers and rapidly changing environments by utilizing the existing R&D process.Existing R&D processes do not reflect the characteristics of the 4th industrial revolution, so they must be changed accordingly. Therefore, it is necessary to develop a new R&D process suitable for this.

The R&D process proceeds to develop a product or service. Comprehensively grasp the related development results step by step, and if there is a problem, the improvement plan is derived and solved. In doing so, it is important to increase the efficiency of achieving the goal and ultimately achieve the goal of the expected development performance. This is carried out in a comprehensive step, and a lot of research has been done in this regard. This study examines the results of previous studies related to various existing R&D processes. Among them, the characteristics of the existing R&D process were examined, focusing on the Stage-Gate process proposed by Cooper. And the purpose is to propose an R&D process suitable for the era of the 4th industrial revolution by analyzing the contents and processes that change according to the times (Cooper, 1990).

The purpose of this study is to examine various prior studies on the existing R&D process and examine its characteristics and limitations.Second, it analyzes the characteristics of the era of the 4th industrial revolution that will lead to innovative changes in the overall industry.Based on this, we derive implications and propose a new R&D process suitable for this.

2. THEORETICAL BACKGROUND AND PRIOR RESEARCH

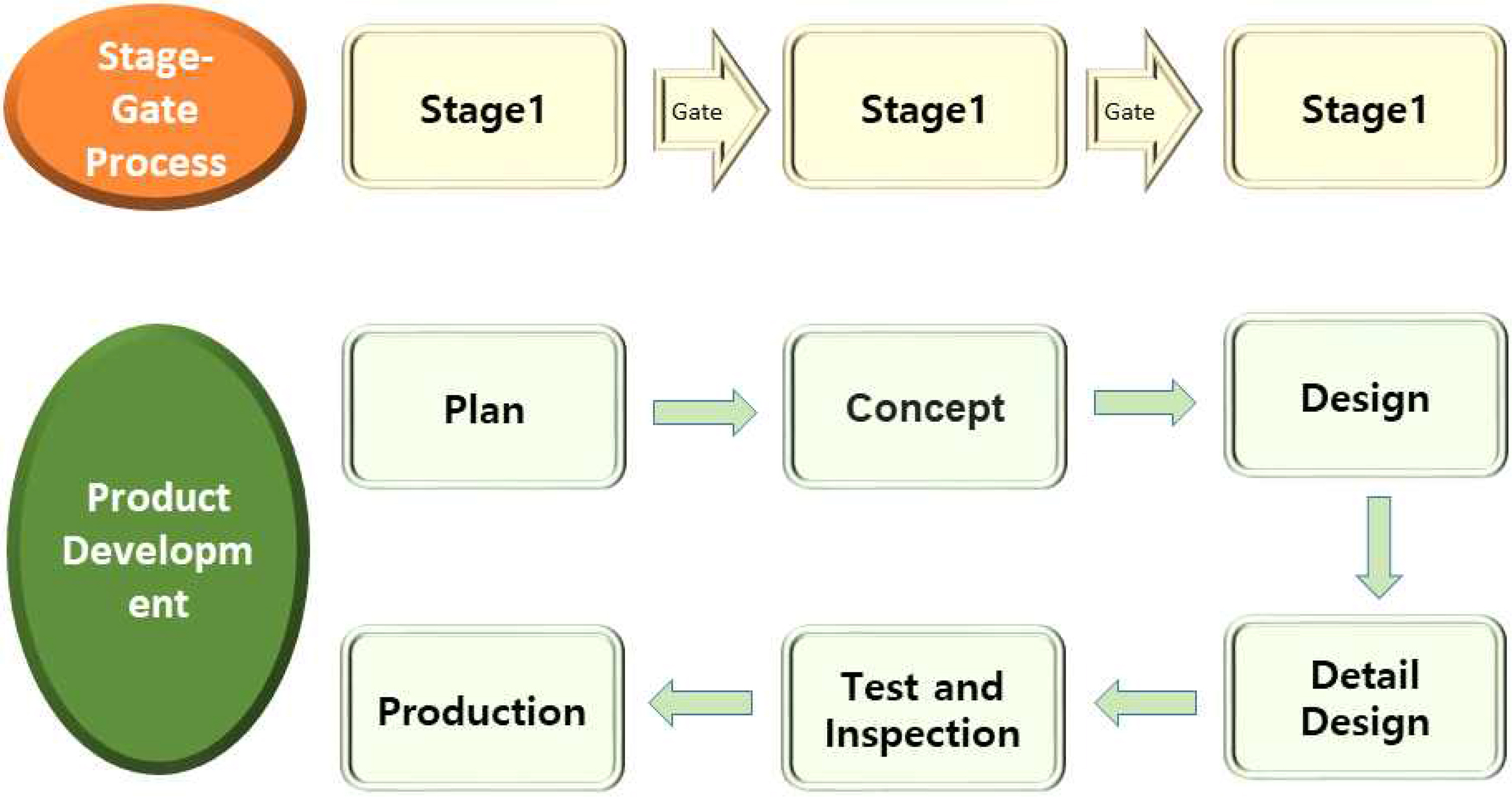

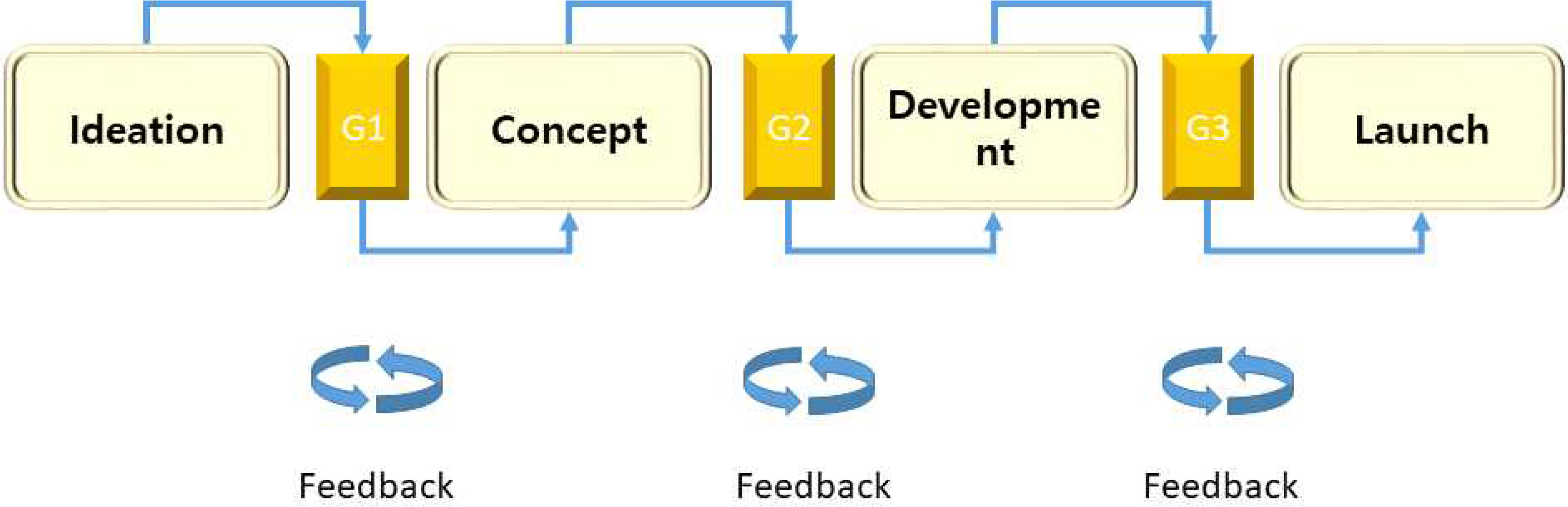

R&D activities generally consist of several step-by-step processes from recognition of opportunities for new product development to design and development, prototype production and market introduction. This process continues through step-by-step execution and feedback. Several methods are used for the R&D development process. Among them, SGP (Stage-Gate Process) defines development activity as a stage, and activity evaluation and decision-making as a gate. It is largely divided into five stages, and is used by establishing a project plan, defining specifications for specification analysis and development, developing detailed designs, product inspection and verification, and market launch. When the execution of each stage is completed, the process goes through the gate to evaluate the process and result in stages.

In the R&D process, Design for Six Sigma (DFSS) is sometimes used. In general, the process of using DFSS in the R&D process is divided into five steps. First of all, the 'Define' step is the step of defining the problem by identifying the problem that has occurred and the core requirements of the customer. The second is the 'Identify' step to identify the current level and to check the product specifications by checking the customer's requirements. The third is the 'Design' stage, which selects the main factors in the process and design the related contents. The fourth is the 'Optimize' step, which goes through a detailed design process and optimizes it. Finally, in the 'Validate' stage, the related results are tested and verified using prototypes.

The R&D process utilizes a general product development theory. This is divided into a step of developing a concept of a product (Concept Development), starting with a product planning step (Plan), and a system design for this (System Design). And it is divided into a step of performing detailed design (Detail Design), a step of performing related tests and inspections (Test). And finally, it can be divided into a production process. Each step can be broken down in more detail. For example, the concept development stage of a product is first divided into the stage of analyzing consumer needs, the second stage of selecting a product concept, the third related testing stage, the fourth stage of determining the final product specification, and finally the stage of designing a suitable product. In summary, it can be expressed as Figure 1.

Existing R&D process research studies the definition of the purpose of the activity at the input stage of the process. In addition, in the process development stage, the use of the method of activity and its appropriateness are investigated. In the calculation stage, we study the definition and existence of the final product. And in the result stage, we study the definition and existence of results for the process. In addition, a model developed by reflecting the concept of the value chain model of R&D process activities was also studied.

Cooper (1994) investigated existing studies on the R&D process. Through this, it was recognized that there was a system that promotes new product projects from ideas to new product development, but there is a weakness that takes a long time. Therefore, a study focused more on the management of the project portfolio and resource management. It also studied an efficient roadmap to bring products to market faster and improve the use of scarce resources. In order to provide this to companies, a basic process for successful R&D activities was proposed.

Edgett et al. (2002) divided the development of new products using the R&D process into organizational level and project level. In addition, detailed activities for new product development activities were defined as Best Practices. The best practices for this were classified into major activities such as new product strategy reflecting corporate goals, new organizational culture, project cooperation team composition, and project resource allocation. This was again classified into sub-categories and composed of about 100 best practices.

Yasin (2002) reviewed a variety of literature related to benchmarking cases and theories for best practices. Benchmarking of best practices emphasized the process and direction of activities in the early stages of development of the R&D process. Since then, the scope has been expanded to include strategies and systems, and it has been recognized as a means of enabling companies to enhance their competitiveness. And it was used as a useful tool for improving the product process.

Cooper and Edgett (2006) proposed an efficient and improved R&D process by using and grafting the Agile development process started in the software field. Originally, the Agile development process began with the Manifesto for Agile Software Development. Initially, it was used by software companies, and then gradually expanded to start-ups and IT companies. The Agile development process does not prefer to roll out a product after planning it completely from scratch. It is important to make products quickly in a short development period and to share continuous results by repeating modifications while executing them. Therefore, it was implemented focusing on the implementation of required major functions by reflecting the immediate requirements of users.

Recently, it has developed into an integrated Agile-Stage-Gate hybrid process model by taking advantage of the Stage-Gate process and the Agile development process methodology.

Cooper (2007) has integrated the Agile element into the existing Stage-Gate process among the IT product development methods. In addition, the R&D process for developing physical products was studied. This is the complement of the Agile and Stage-Gate methods. It began in the IT industry and gradually spread to a variety of companies, including manufacturing companies. This Agile-Stage-Gate hybrid process model is faster than ever before product development and launch, and responds to changing customer requirements step by step. In addition, the R&D process developed by systematically improving team communication and efficiency was proposed. The detailed method and process for this is shown in Figure 2.

Conforto and Amaral (2016) analyzed the hybrid R&D process and management framework that combined Agile with the Stage-Gate model. For Agile development process, H. In proposed a scrum-based development process using simultaneous testing as a way to improve product quality and reduce waste of time (In, Hoh et al., 2012).

Seong joo Lee analyzed the characteristics of R&D activities and defined the R&D process based on this, and derived detailed activities for each R&D process suitable for each type (Lee, Sung Joo et al., 2012).

Huang and Han provided a guide to improving the organization's process capabilities for the development, evaluation and maintenance of software, products and services using CMMI (Haung, S. J. and Han, W. M., 2006).

3. RESEARCH MODEL

The 4th Industrial Revolution in the global era formed a complex and fused industrial structure by combining multiple frames connected by a hyper connected society and super intelligent technology. It is creating an economic and social environment where challenges are possible to solve various complex problems. This is not just a change, but a big paradigm change in society, economy and various industries. Reflecting this, it is necessary to study and propose the R&D process.

Due to the DX, it is possible to order products and services based on customer-specific products that can reflect the individuality and utility of each consumer. And it is changing into a society that produces customized products.

The existing R&D process is formed by a company-centered, technology-centered and market-based offline structure and is mainly operated. However, in the DX era, these R&D processes will rapidly shift to customer service based on new fusion technology and complex marketability. These parts raise the bar for predicting the products and services they want, based on various preliminary surveys of customer needs, and ultimately the customer's active participation in ordering and development.

In addition, the idea creation and product planning stages proceed in sequence, but there are parts that proceed together in parallel, and for that reason, cooperation between related departments is rapidly carried out. This shows the same phenomenon at the product design, product development, testing and verification, mass production and launch stages, shortening the overall R&D process schedule. The core here is that the R&D process is flexible and immediate with a parallel structure to respond quickly to rapidly changing markets and diverse customers, rather than simply reducing the overall schedule of the R&D process.

Therefore, it is expected that the structure of the R&D process will change to a cyclical structure in the future and develop into a system that responds flexibly in real time. The length (constant) of each stage can be flexibly changed depending on the form and content of the product or service, and the cyclic stage should be advanced once or multiple times by utilizing virtual simulation. Through intelligent systems such as AI and Big Date during the DX and real-time communication, changes and needs of markets and customers can be analyzed immediately and responded immediately. In addition, each step can proceed in the form of modularization that is partially omitted or merged depending on the form and content of the product or service.

4. Conclusion

By developing R&D processes that reflect the characteristics of the DX era, companies can provide products and services tailored to their customers, increasing efficiency and satisfaction. It can also develop and build R&D processes for the new era and run processes that reflect the benefits and benefits of consumers. These studies will provide companies with diverse and groundbreaking opportunities by presenting new strategies and strategies through proposals for R&D process development suitable for the DX.

This study examines the research on the existing R&D process and examines the characteristics of general product development and the development of the Stage-Gate-centered R&D process. In addition, we analyzed the characteristics of the DX era and suggested a new R&D process suitable for it. This study has several limitations. A step-by-step concrete study on the R&D process in the DX era is needed. And it is necessary to study the definition and content of Best Practice, which is a detailed step-by-step element. In addition, detailed research on the specific composition and related contents is required so that companies can directly utilize the new R&D process. Case studies applying this should also be conducted concurrently.

As additional research in the future, it is necessary to propose an evaluation method for a new R&D process. Along with the development of the R&D process in the DX era, additional research is needed to develop an index that can evaluate it fairly and flexibly.